The Advantages

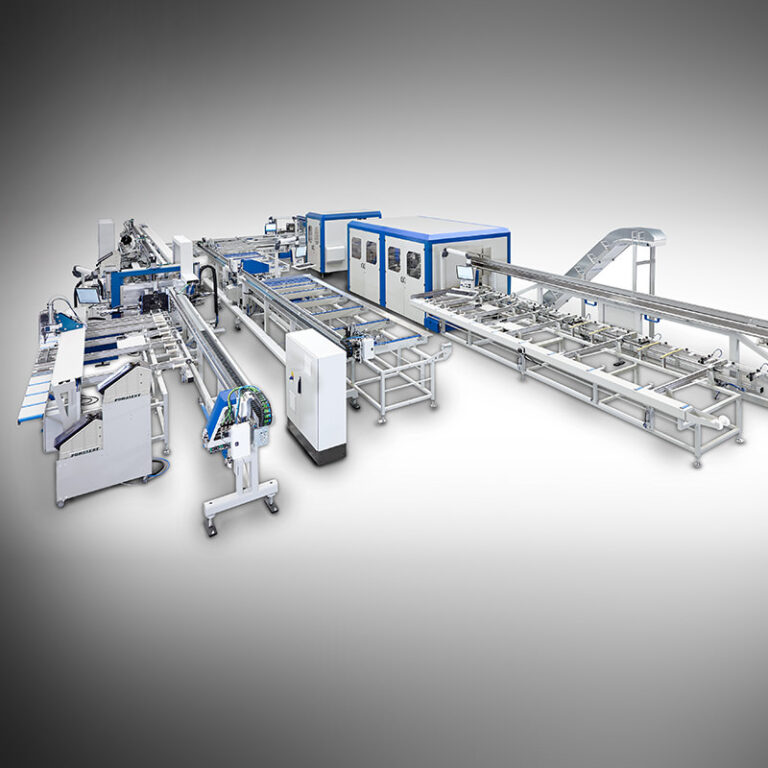

- Complete processing of PVC window and front door profiles with a production capacity of approx. 180 to 220 window units per shift

- ParallelProcessing: Shorter machining cycles by decou- pling the machining operations on the bar

- Bottom runner for permanent fitting of the screws… (optional)

- Ease of use and data maintenance

- Freely programmable processing data

- Profile rod systems PVC / PVC-steel-reinforced composites

- Additional functions such as variable saw, inline printer, gasket undercutting and transom milling station with changer, automatic clamping part setting and screwing station and stacking system possible

TECHNICAL DATA

Magazine feed10 spaces Length of profile barmin. 650 mm Length of profile barmax. 6500 mm Cutting lengthmin. 326 mm Cutting lengthmax. 4006 mm (optional 6006 mm) Profile view width130 mm Profile depth120 mm (optional 180 mm)

Persönliche Beratung?

Unsere kompetenten Ansprechpartner helfen Ihnen gerne und beraten Sie persönlich.

KontaktPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

ContactPERSONAL ADVICE?

Our competent contact persons will be happy to help you and advise you personally.

ContactPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

ContactPOTRZEBUJESZ WSPARCIA SPECJALITY?

Nasi kompetentni pracownicy chętnie pomogą i osobiście doradzą.

Kontakt¿ASESORAMIENTO PERSONALIZADO?

Nuestras personas de contacto competentes con gusto lo ayudarán y lo asesorarán personalmente.

CONTACTOPERSOONLIJK ADVIES?

Onze deskundige contactpersonen helpen u graag en adviseren u persoonlijk.

CONTACTCONSULTANTA PERSONALIZATA?

Echipa noastra experimentata va fi onorata sa va asiste si sfatuiasca personal.

CONTACTПЕРСОНАЛЬНАЯ КОНСУЛЬТАЦИЯ?

Наши компетентные контактные лица охотно помогут вам и предоставят персональную консультацию.

СВЯЗЬPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

Contact