The Advantages

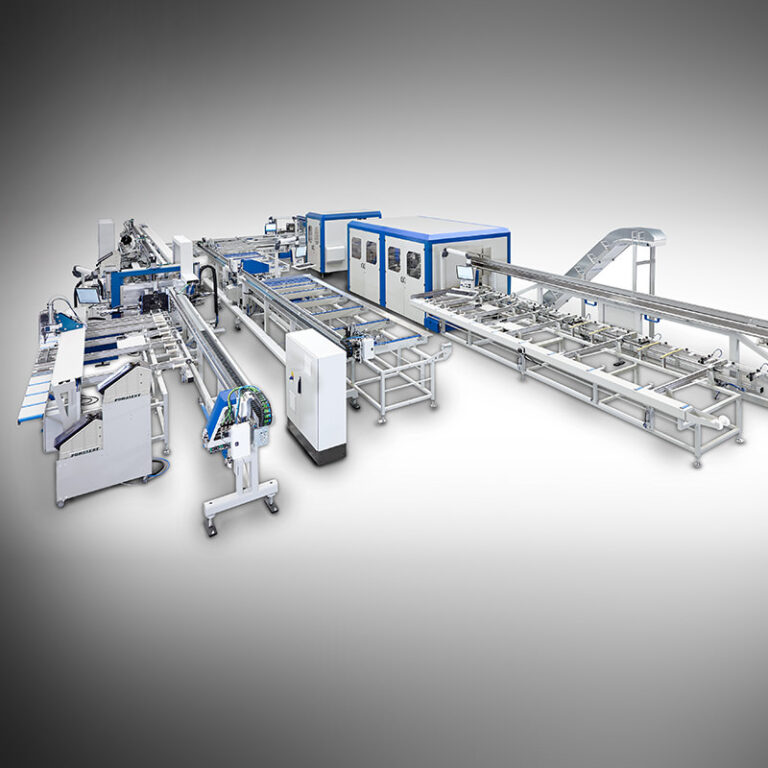

- Cutting and rod processing centre for processing PVC windows and front door profiles with a production output of up to 120FE/8h

- Automatic indexing feed magazine Pusher axes with linear guide and rack and pinion drive with automatically controlled gripper positions

- Upstream 2-axis PVC processing module

- Cutting saw from below in different model variants: 45°, 90°, -135° or variable angles up to 30°

- Cross conveyor system Profile system-independent, process-orientated cross conveyor system Transport system (QFSIPT)

- Reinforcement station with 6 reinforcement compartments including TFT screen display

- Cycle time optimised reinforcement screwing

- 2-axis NFZ processing module for PVC and steel processing

- Outfeed sliding table (optional belt conveyor)

- The intuitive information management system offers visualisation of profile cross-sections and processing as well as a diagnostics and reporting tool and maintenance management, plus other options

- On-screen dialogue system under Windows with loading table display Freely programmable processing data (incl. internet-based online remote service maintenance)

TECHNICAL DATA

Feed magazine 9 places Profile bar length min. 1000 mm Profile bar length max. 6 500 mm Profile cutting length max. 4 006 mm Profile face width max. 130 mm Profile construction depth 120 mm Tool positions up to 32 Cutting accuracy + / – 0.3 mm (independent of profile tolerance)

Persönliche Beratung?

Unsere kompetenten Ansprechpartner helfen Ihnen gerne und beraten Sie persönlich.

KontaktPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

ContactPERSONAL ADVICE?

Our competent contact persons will be happy to help you and advise you personally.

ContactPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

ContactPOTRZEBUJESZ WSPARCIA SPECJALITY?

Nasi kompetentni pracownicy chętnie pomogą i osobiście doradzą.

Kontakt¿ASESORAMIENTO PERSONALIZADO?

Nuestras personas de contacto competentes con gusto lo ayudarán y lo asesorarán personalmente.

CONTACTOPERSOONLIJK ADVIES?

Onze deskundige contactpersonen helpen u graag en adviseren u persoonlijk.

CONTACTCONSULTANTA PERSONALIZATA?

Echipa noastra experimentata va fi onorata sa va asiste si sfatuiasca personal.

CONTACTПЕРСОНАЛЬНАЯ КОНСУЛЬТАЦИЯ?

Наши компетентные контактные лица охотно помогут вам и предоставят персональную консультацию.

СВЯЗЬPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

Contact