The Advantages

- 2 Highly dynamic electric screwdriving units

- Processing of up to eight different euro groove heights – independent of profile and fitting system

- Maximum output through the use of highly dynamic modules and intelligent control technology

- Gentle bolting of the sash corner bands

- The highly innovative control technology combines a database-oriented screen dialogue system with a powerful control system arm

- The intuitively operated information management sys- tem offers visualisation of all hardware data, a diagno- sis and reporting tool and maintenance management, as well as other options

- Integrated remote maintenance avoids the need for on-site service technicians

- Automatic stacking (optional)

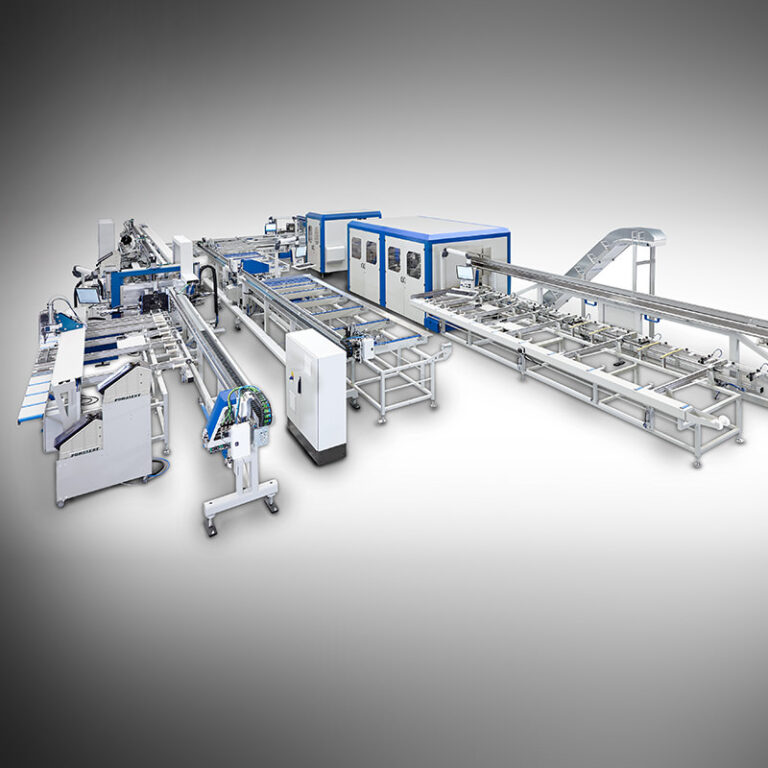

- Integratable into manufacturing line

- Preassembly table for hardware with compartments for long hardware parts and corner deflection units

- To ensure a continuous material flow in the production process, the sash cutter is folded in via a tensioning arm

- Completely bolted sashes are automatically trans- ferred orderly into a vertical element buffer

TECHNICAL DATA

Profile depthmin. 60 mm Profile depthmax. 100 mm* Profile view widthmin. 69 mm (for mullion profile of 49 mm) Profile view widthmax. 130 mm / 150 mm* Euro groove heightmin. 30 mm Euro groove heightmax. 50 mm Width of casement rebatemin. 280 mm* Width of casement rebatemax. 1600 mm* Height of casement rebatemin. 280 mm Height of casement rebatemax. 2600 mm Width of casement glass rebatemin. 220 mm Height of casement glass rebatemin. 220 mm Weight of casementmax. 100 kg Cycle time< 1,5 minutes (depending on type of fitting) Profile systemsPVC / PVC steel-reinforced pro files/composites

Persönliche Beratung?

Unsere kompetenten Ansprechpartner helfen Ihnen gerne und beraten Sie persönlich.

KontaktPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

ContactPERSONAL ADVICE?

Our competent contact persons will be happy to help you and advise you personally.

ContactPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

ContactPOTRZEBUJESZ WSPARCIA SPECJALITY?

Nasi kompetentni pracownicy chętnie pomogą i osobiście doradzą.

Kontakt¿ASESORAMIENTO PERSONALIZADO?

Nuestras personas de contacto competentes con gusto lo ayudarán y lo asesorarán personalmente.

CONTACTOPERSOONLIJK ADVIES?

Onze deskundige contactpersonen helpen u graag en adviseren u persoonlijk.

CONTACTCONSULTANTA PERSONALIZATA?

Echipa noastra experimentata va fi onorata sa va asiste si sfatuiasca personal.

CONTACTПЕРСОНАЛЬНАЯ КОНСУЛЬТАЦИЯ?

Наши компетентные контактные лица охотно помогут вам и предоставят персональную консультацию.

СВЯЗЬPERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.

Contact