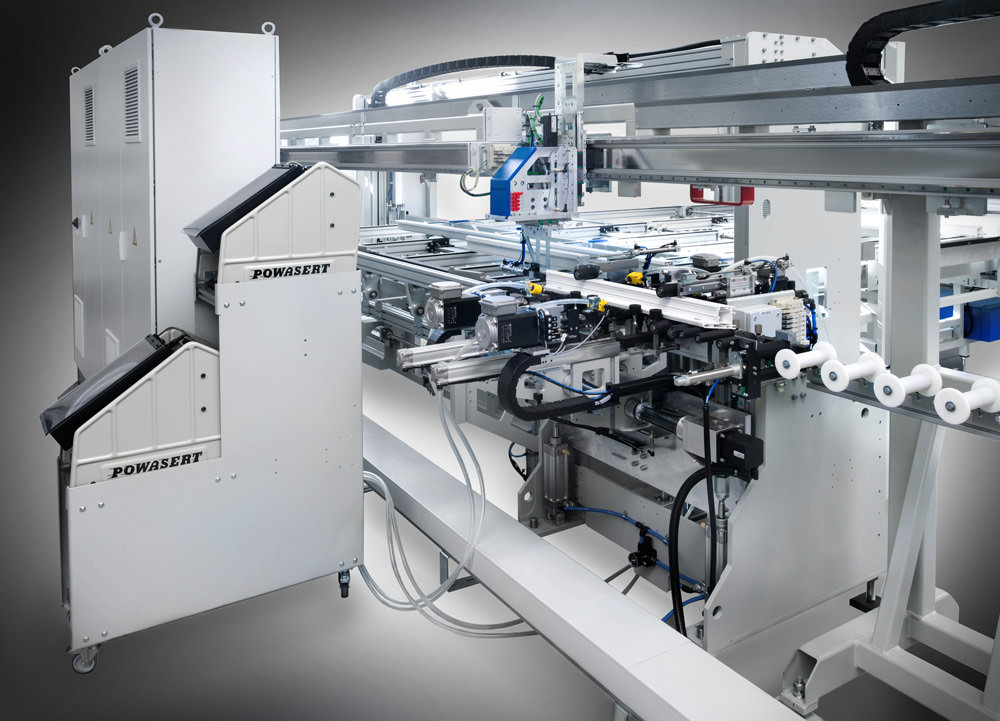

PowerCenter-PP

Products / Bar processing

The Advantages

- Complete processing of PVC window and front door profiles with a production capacity of approx. 180 to 220 window units per work shift.

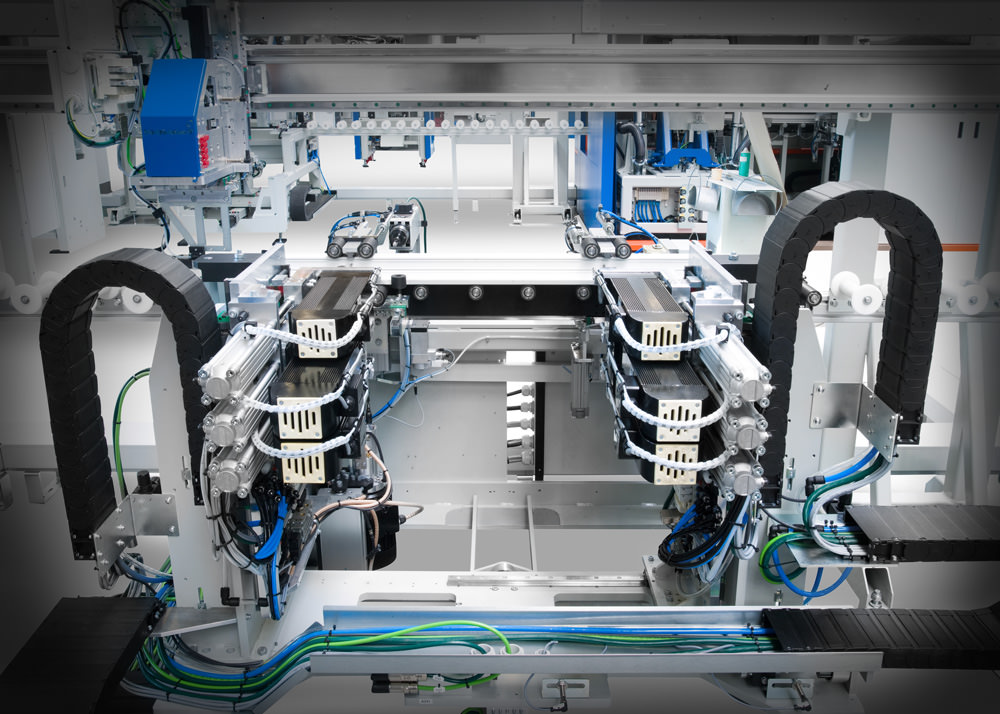

- ParallelProcessing: Shorter processing cycles by decoupling the machining on the profile bar

- Easy to use and simple data maintenance

- Processing data randomly programmable

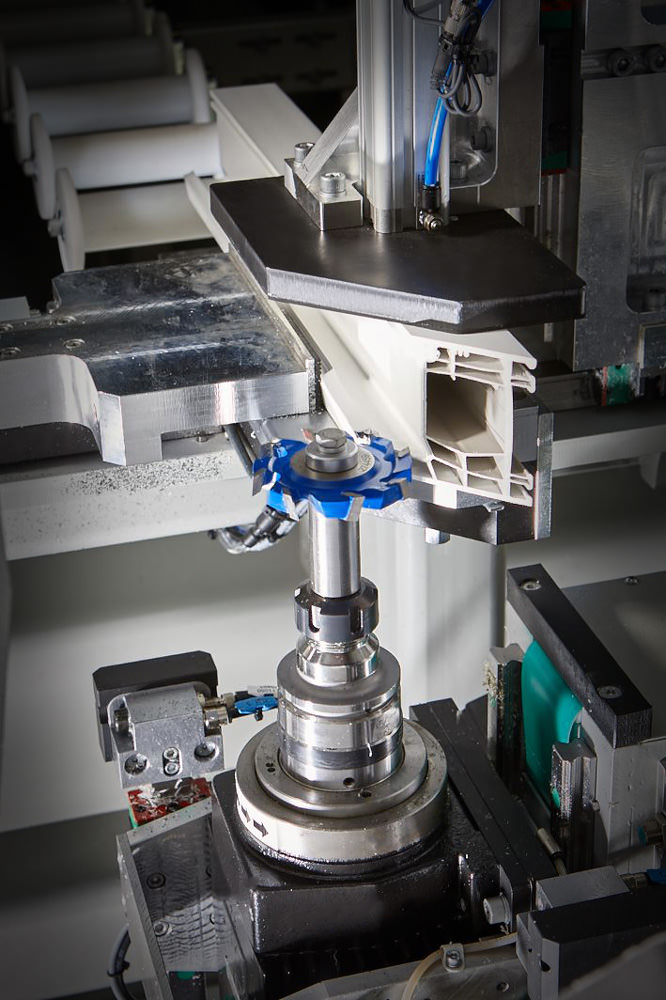

- Profile bar systems PVC/PVC steel reinforced composites

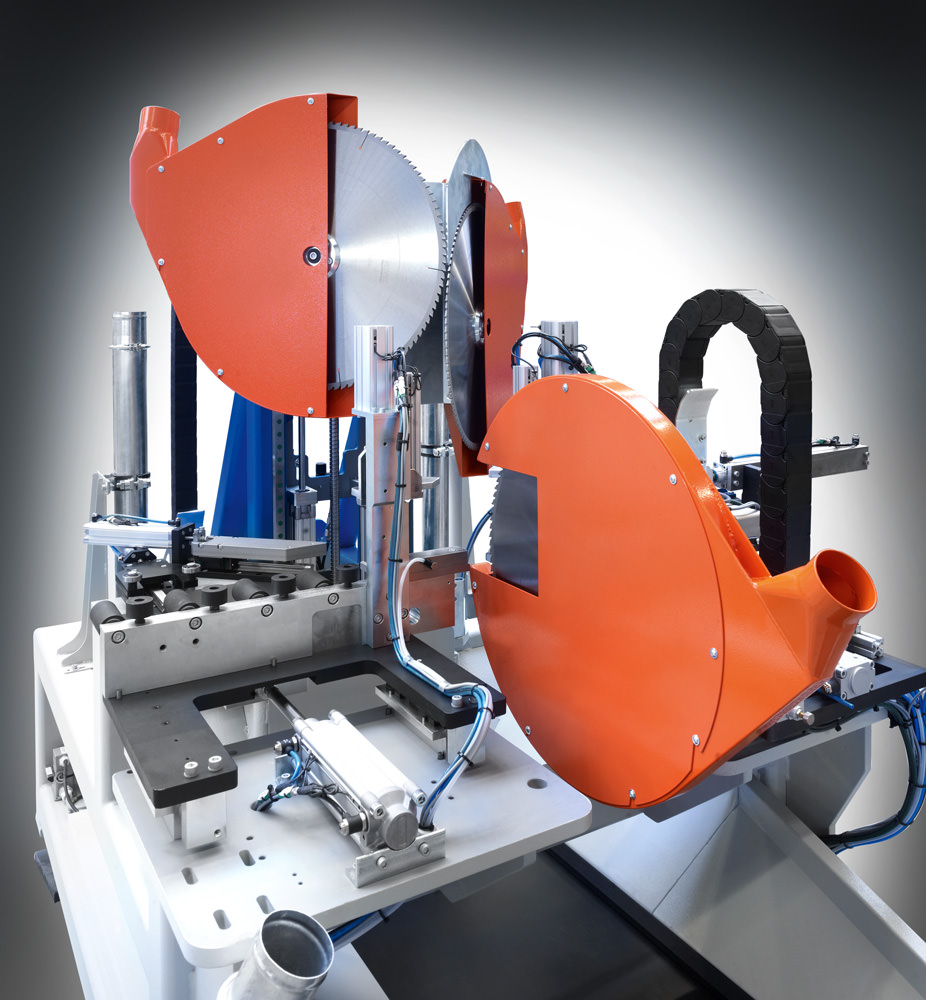

- Additional functions such as variable saw, inline printer, seal undercutting and transom cutting station with changer, automatic closing part setting and screwing station and stacking system possible

The Advantages

- Complete processing of PVC window and front door profiles with a production capacity of approx. 180 to 220 window units per shift

- ParallelProcessing: Shorter machining cycles by decou- pling the machining operations on the bar

- Bottom runner for permanent fitting of the screws… (optional)

- Ease of use and data maintenance

- Freely programmable processing data

- Profile rod systems PVC / PVC-steel-reinforced composites

- Additional functions such as variable saw, inline printer, gasket undercutting and transom milling station with changer, automatic clamping part setting and screwing station and stacking system possible

Exact positioning

due to ZeroPointDetection

Highly dynamic pusher systems

with process decoupling for cycle time reduction

Intuitively operable

Information Management System

Technische Daten

Magazine feed 10 spaces

Length of profile bar min. 650 mm

Length of profile bar max. 6500 mm

Cutting length min. 326 mm

Cutting length max. 4006 mm (optional 6006 mm)

Profile view width 130 mm

Profile depth 120 mm (optional 180 mm)

PERSONALISED CONSULTATION?

Our experienced contact personnel will be happy to assist you and advise you personally.